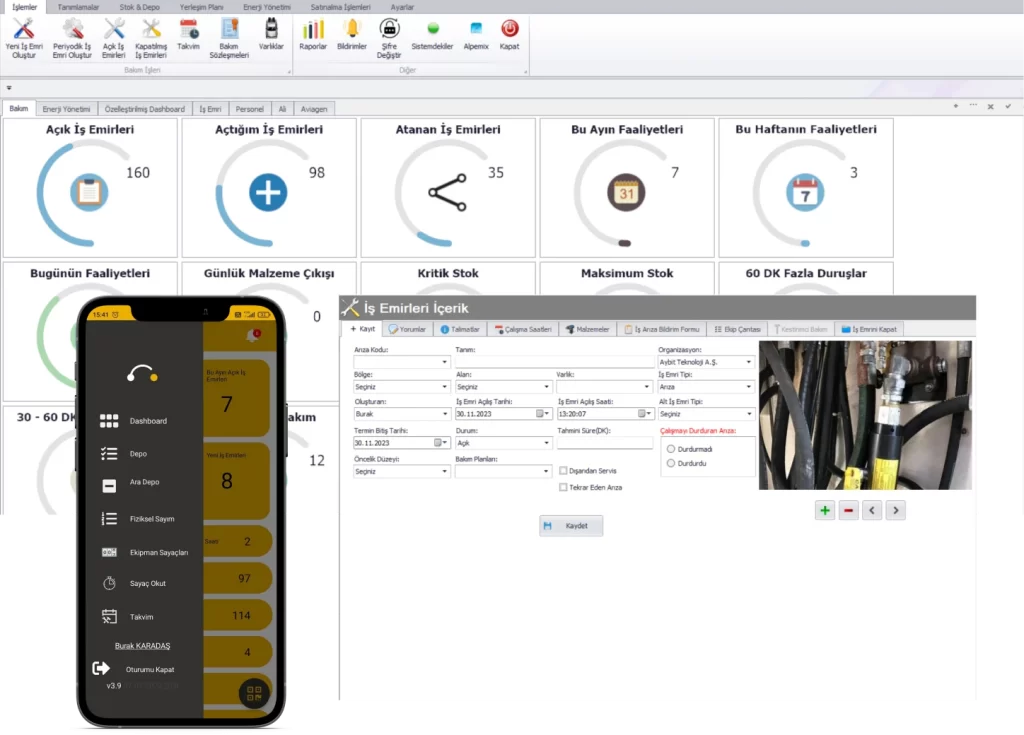

Increase Your Productivity with repairist

Maintenance Management Software

Discover the advantages of maintenance management by reducing breakdowns and shortening repair times with your maintenance management software. Is your teamwork planned and organised, or do individual efforts stand out? Do you have a corporate maintenance culture or do you need improvement in this area?

Are your digital maintenance record systems accessible to all team members quickly and effectively? Are you capable of predicting future failures? It is possible with repairist maintenance management software.

What are the Benefits of repairist Maintenance Management Software?

Automatisation

- Enables to record field activities via maintenance mobile application.

- You can record stock usage, document viewing and activity notes instantly and completely.

Automatising Maintenance Operations

- repairist enables integrated and automatic planning and management of maintenance activities based on production quantities.

Documentation Management

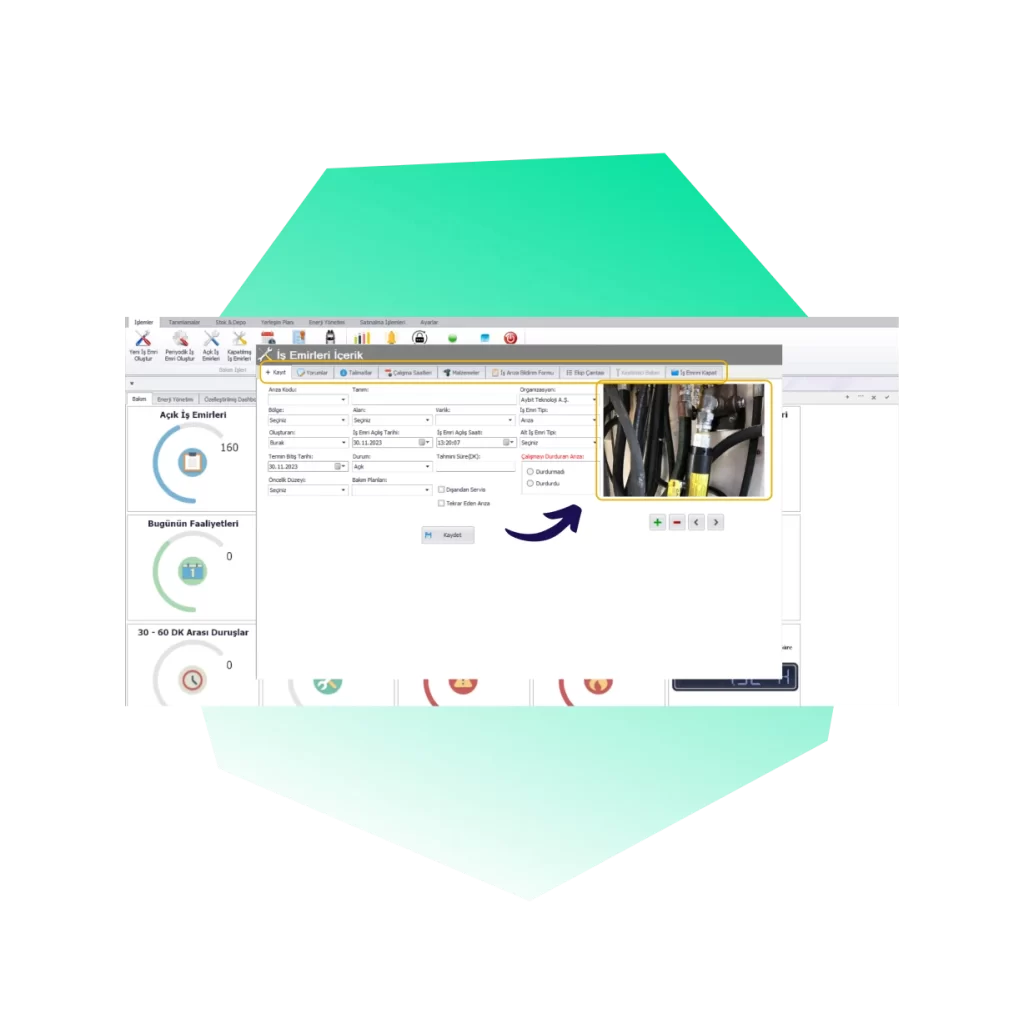

- Maintenance management software facilitates the management of maintenance documents.

Monitoring and Analysis

- Maintenance activities and performance are monitored and analysed.

Predictive Maintenance

- Predictive maintenance, performed using artificial intelligence algorithms, detects potential failures in advance, takes precautions and prevents the need for long-term repairs.

Staff Notifications

- When defined situations occur or maintenance periods are approaching, the relevant personnel are automatically notified.

Fast Communication

- Quick maintenance requests can be created via KeyPDT, EPC or PC, so that maintenance needs are quickly communicated and intervened.

Inventory Management

- Spare parts stocks are managed effectively.

Maintenance Management Software: How Does It Improve Your Business Efficiency?

In the modern business world, regular and effective equipment maintenance plays a critical role in ensuring the continued efficiency and steady growth of businesses. Maintenance Management Software (MMS) facilitates these processes, enabling businesses to maximize the efficiency of their time and resources.

Maintenance management software is a basic need in any manufacturing or service sector. Equipment failures, unexpected downtime, and inefficient maintenance programs can increase costs and disrupt production processes. BYY increases the continuity and efficiency of businesses by effectively managing these problems.

Functions of Maintenance Management Software

Periodic Maintenance Planning

Prevent unexpected breakdowns by planning the maintenance of equipment at regular intervals.

Performance Analysis

Prevent unexpected breakdowns by planning the maintenance of equipment at regular intervals.

Inventory Management

Manages the stocks of necessary spare parts and materials and prevents deficiencies.

Breakdown Monitoring and Management

Provides fast detection and elimination of faults.

Benefits of Maintenance Management Software

Cost Savings

Regular maintenance and effective fault management lead to cost savings in the long term.

Production Sustainability

Regular maintenance of the equipment guarantees continuity of production.

Data-Driven Decision Making

MMS supports data-driven decision-making processes.

By optimizing the maintenance processes of enterprises, it provides both cost savings and production efficiency. This software has become an indispensable tool for businesses of all sizes.