Computerized maintenance management systems (CMMS) play a crucial role in modern asset management. If you’re looking for key insights about CMMS adoption, trends, and impact, you’re in the right place.

This article explores ten significant statistics that showcase how CMMS is evolving. It also covers why companies are embracing it and how it can transform maintenance operations.

Table of Contents

- 8% of Managers Struggle with CMMS Data Accuracy

- CMMS Plays a Major Role in Asset Management

- 70% of Companies Use CMMS for Maintenance

- CMMS Market Expected to Reach $4.5 Million by 2033

- 75% Say CMMS Increases Efficiency

- 50% of CMMS Users Implement Predictive Maintenance

- 30% Report Reduced Unplanned Downtime with CMMS

- 22% of Companies Use Only Basic CMMS Functions

- 60% of CMMS Adopters Migrated from Spreadsheets

- 65% of Companies Plan to Invest More in CMMS

- Next Steps

- Frequently Asked Questions

8% of Managers Struggle with CMMS Data Accuracy

Data quality remains a challenge for some users, with 8% of maintenance managers citing inaccurate or incomplete data as a major issue. Ensuring proper data entry, regular updates, and standardized processes can help mitigate this problem.

CMMS Plays a Major Role in Asset Management

CMMS now accounts for a significant share of the global asset management market, proving its value in optimizing maintenance strategies. Companies in manufacturing, construction, and utilities rely on CMMS to streamline preventive maintenance. This helps improve asset lifespan.

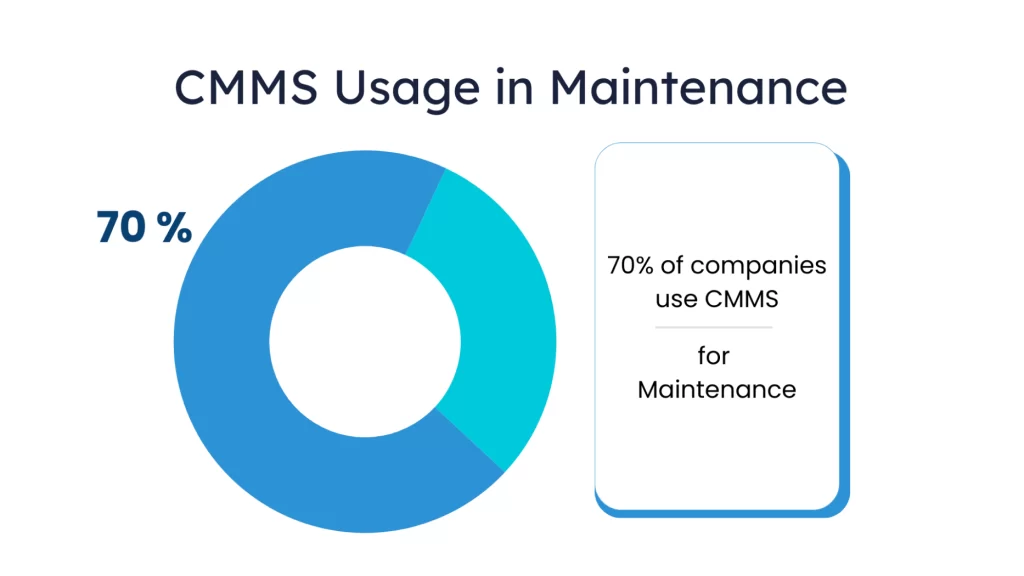

70% of Companies Use CMMS for Maintenance

A survey of maintenance professionals found that 70% use CMMS primarily to organize maintenance tasks, work orders, and asset tracking in a centralized system. This digital approach minimizes inefficiencies and improves workflow management.

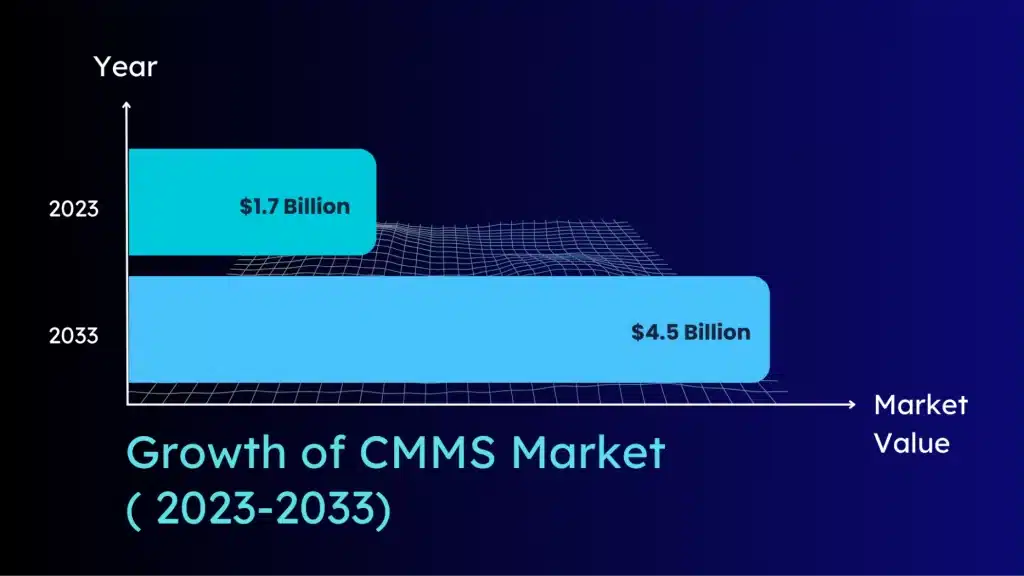

CMMS Market Expected to Reach $4.5 Million by 2033

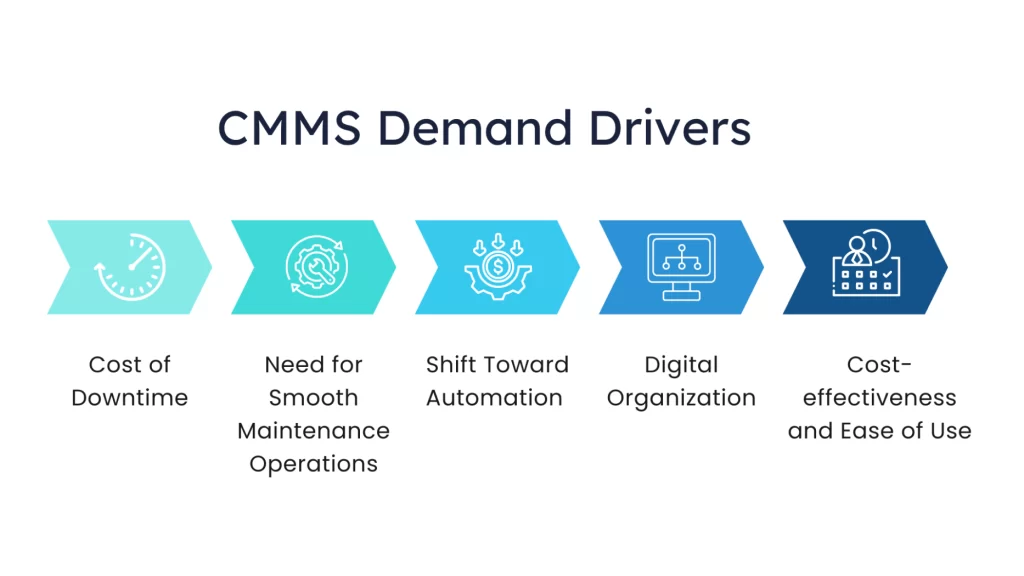

Market research indicates that the CMMS market will grow substantially over the next decade. Projections suggest an increase from $1.7 Billion in 2023 to $4.5 Billion by 2033. This reflects a compound annual growth rate of approximately 9.5%.

75% Say CMMS Increases Efficiency

Maintenance teams using CMMS report notable productivity gains, with 75% stating that the software has streamlined their operations. Features such as automated scheduling, real-time reporting, and mobile access contribute to these efficiency improvements.

50% of CMMS Users Implement Predictive Maintenance

Half of CMMS users leverage predictive maintenance capabilities. They integrate their systems with IoT sensors to analyze equipment performance. This allows them to schedule maintenance before failures occur. This proactive strategy is becoming a standard feature in modern CMMS solutions.

30% Report Reduced Unplanned Downtime with CMMS

Reducing downtime is a priority for many businesses. 30% of CMMS users report that their systems have significantly decreased unexpected breakdowns. By enabling predictive maintenance and real-time monitoring, CMMS helps prevent costly disruptions.

22% of Companies Use Only Basic CMMS Functions

While many companies take advantage of advanced CMMS features, 22% focus solely on core functions such as work order management, asset tracking, and maintenance scheduling. The majority (78%) are looking for additional features such as service management and parts management. They also seek health and safety compliance and integration with sensors for predictive maintenance. This highlights the diverse needs of businesses implementing CMMS.

60% of CMMS Adopters Migrated from Spreadsheets

Despite the advantages of CMMS, many organizations still rely on spreadsheets. However, 60% of recent adopters transitioned from manual tracking systems to CMMS. They are seeking automation, improved accuracy, and better data management.

65% of Companies Plan to Invest More in CMMS

With the increasing demand for efficient maintenance solutions, 65% of businesses plan to expand their CMMS investments in the next five years. Companies are looking to enhance system integrations. They also aim to adopt AI-driven analytics and improve maintenance automation.

These ten statistics emphasize the growing importance of CMMS in modern maintenance management. CMMS is transforming the way businesses manage their assets. As adoption rates rise and technology advances, investing in a CMMS will be crucial for companies aiming to optimize their maintenance strategies and reduce operational costs.

Next Steps

Have you received sufficient information about “CMMS: 10 Key Statistics and Insights You Should Know“?

repairist is here to help you. We answer your questions about the Maintenance Management System and provide information about the main features and benefits of the software. We help you access the repairist demo and even get a free trial.

Aybit Technology Inc.

Frequently Asked Questions

Statistics provide data-driven insights into the effectiveness of CMMS software, helping businesses understand industry trends, ROI, and best practices for maintenance management.

CMMS optimizes maintenance workflows by reducing downtime, improving asset reliability, automating preventive maintenance schedules, and ensuring compliance with safety and regulatory standards.

By preventing unexpected breakdowns, minimizing unplanned downtime, and optimizing resource allocation.