Digitalise With repairist

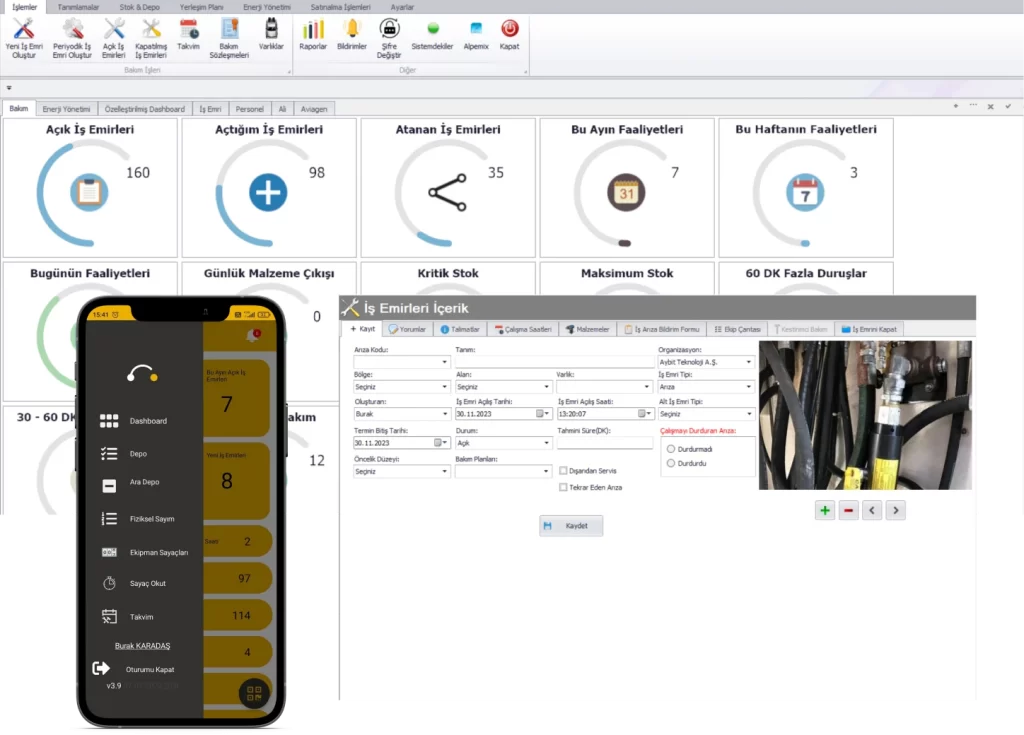

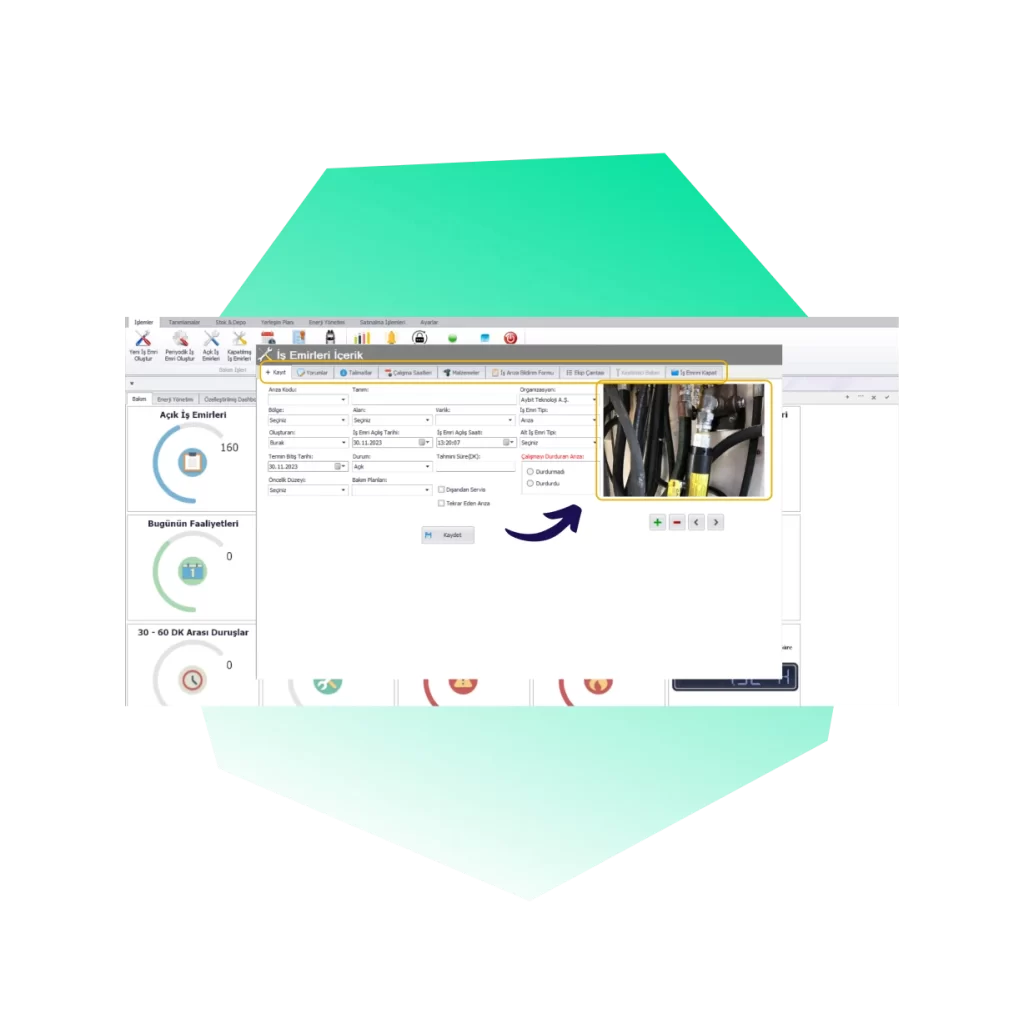

CMMS Software

Discover the benefits of maintenance management by reducing breakdowns and shortening repair times with CMMS software. Is your teamwork planned and organised, or do individual efforts stand out? Do you have a corporate maintenance culture or do you need improvement in this area?

Are your digital maintenance record systems accessible to all team members quickly and effectively? Are you capable of predicting future failures? It is possible with maintenance management software.

What are the Benefits of repairist Maintenance Management Software?

Mobile CMMS

- Enables recording of field activities with the maintenance mobile application.

- You can record stock usage, document viewing and activity notes instantly and completely.

Automating Operations

- repairist enables integrated and automatic planning and management of maintenance activities according to production quantities.

Documentation Management

- Maintenance management software facilitates the management of maintenance documents.

Monitoring and Analysis

- Bakım aktiviteleri ve performansının izlenmesi ve analizi yapılır.

Predictive Maintenance

- Maintenance activities and performance are monitored and analysed.

Staff Notifications

- When defined situations occur or maintenance times are approaching, the relevant personnel are automatically notified.

Fast Communication

- Quick maintenance requests can be created via KeyPDT, EPC or PC, so that maintenance needs are quickly communicated and responded to quickly.

Inventory Management

- Spare parts stocks are managed effectively.

Benefits of CMMS Software

The main advantages that CMMS software offers to businesses include cost savings, increased productivity and risk management. Cost savings are achieved by extending equipment life through regular maintenance and repairs and preventing sudden breakdowns. This means a significant reduction in maintenance budgets for businesses in the long term. In addition, CMMS software improves labour productivity by automating maintenance activities, allowing employees to focus on more strategic tasks.

In terms of risk management, CMMS software helps businesses comply with compliance and safety standards. By keeping regular maintenance records, the software facilitates compliance with legal requirements and minimises occupational safety risks. In addition, the CMMS system provides real-time alerts about equipment failures and maintenance needs, enabling quick response to potential disruptions.

Functions of Maintenance Management CMMS Software

Periodic Maintenance Planning

Prevent unexpected breakdowns by planning the maintenance of equipment at regular intervals.

Performance Analysis

Maintenance management software analyses the performance of equipment and maintenance processes, providing data for continuous improvement.

Stock Management

Manages the stocks of necessary spare parts and materials and prevents shortages.

Fault Tracking and Management

Provides fast detection and elimination of faults.

Benefits of Maintenance Management Software

Cost Savings

Regular maintenance and effective fault management lead to cost savings in the long term.

Production Continuity

Regular maintenance of the equipment guarantees continuity of production.

Data Based Decision Making

CMMS supports data-driven decision-making processes.

By optimising the maintenance processes of enterprises, it provides both cost savings and production efficiency. This software has become an indispensable tool for businesses of all scales.

CMMS software allows businesses to efficiently manage their maintenance operations. This software is designed to plan regular maintenance of machinery and equipment, prevent breakdowns and reduce overall maintenance costs. Thanks to advanced analytical tools and data reporting features, businesses can easily monitor and continuously improve their maintenance processes using CMMS software.